Weather invited outdoor work.

New shift cam bearing

I used this thread locking fluid on the bypass hose union bolts. Turned out it is quite aggressive so I doubt if I will be able to remove these bolts again should it ever be needed.. I suggest you use a softer (blue) variant.

I used the blue type on the other bolts.

Bottom view with water pump installed.

Liquid gasket ('Suzuki Bond #4' type) at both sides of the water pump gasket.

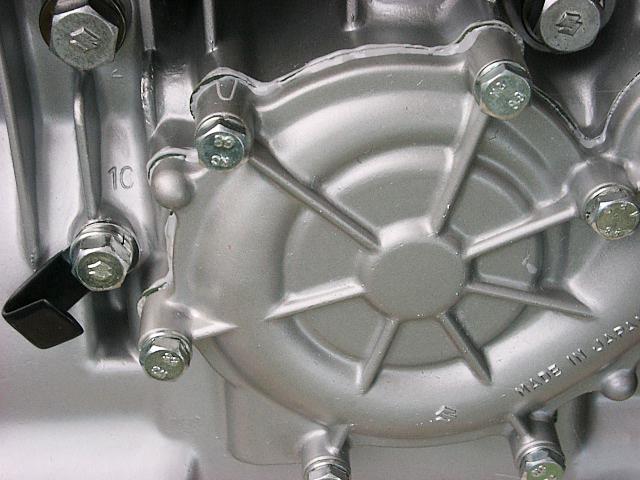

Case reassembled with new crank installed. This crankshaft is of the later style with floating big ends and where thrust washers are used at the small end. It requires the later type of pistons, see this page.

Front view of bottom case

The 06004 washers are aluminium washers that has superceded the plastic washers used on oil line union bolts. They are soft and become compressed when bolt is tightened.

NOS oil line assembly from Vintage Parts.

There are six oil lines, three go to cylinder inlets and three lubricate crank bearings.

GT750 Oil Pump Laboratory !

Testing oil pump and priming the oil lines with two stroke oil..

I attached the pump axle to the chuck of a power drill, If you try this, use only one with variable speed so you can rotate the pump slowly, in the engine it runs at low rpm. Do not rev it !

Oil tank hangs from the roof.

Pistons installed, these are 1.0mm OD (2nd over). Cylinder studs a bit corroded but I think they will be usable.